Corrective maintenance plays a crucial role in keeping facilities and equipment running efficiently. While preventive strategies often take the spotlight, the benefits of corrective maintenance are frequently undervalued. This approach, which involves repairing or replacing components after a fault has been detected, can offer a range of advantages that make it not only practical but also cost-effective in many scenarios.

One of the main benefits of corrective maintenance is its simplicity. Unlike preventive maintenance plans that require detailed scheduling and upfront investment, corrective maintenance is reactive and straightforward. Organizations can allocate resources only when a problem arises, allowing for better utilization of staff and reduced idle time. This approach can be particularly effective for systems where failures are infrequent or where the cost of downtime is lower than the cost of regular inspections.

Another significant advantage is cost control. Rather than spending money on routine checks and replacements that may not be necessary, businesses can focus their budget on actual issues. This allows for more flexible financial planning, especially for smaller operations. In some environments, the cost savings from avoiding unnecessary maintenance can be substantial over time. For those seeking more insight into the advantages of corrective maintenance, there’s growing evidence that supports its strategic use in specific operational settings.

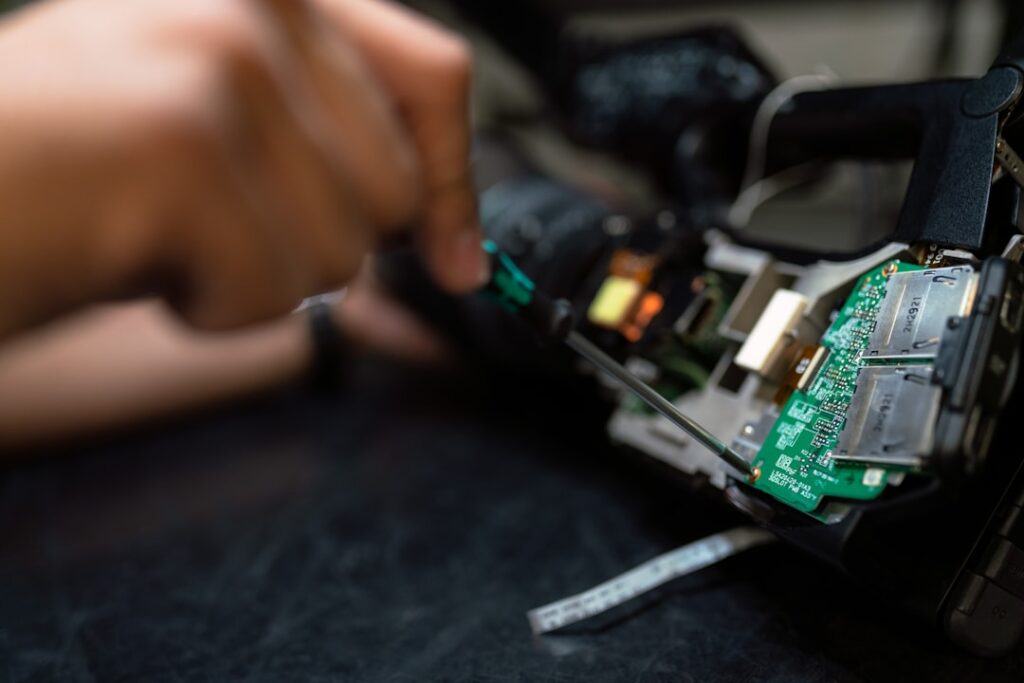

Corrective maintenance also fosters a more targeted approach to problem-solving. When a failure occurs, the response is immediate and focused, often leading to a deeper understanding of the root cause. This can result in long-term improvements to systems and processes, as teams learn from each breakdown and refine their maintenance practices accordingly. Additionally, modern diagnostic tools and technologies have made it easier to quickly identify and address issues, further enhancing the efficiency of corrective maintenance.

In industries where uptime is critical, having a reactive maintenance plan can serve as a valuable complement to other strategies. Instead of over-maintaining equipment, teams can respond to actual wear-and-tear, reducing waste and extending the life of components. This approach can also minimize disruption, as repairs are only carried out when necessary, rather than during routine but potentially intrusive maintenance windows.

For organizations evaluating their maintenance options, resources such as the expert guidance available online can help determine whether corrective maintenance aligns with their operational goals. In many cases, blending corrective with preventive strategies offers the most balanced and effective solution.

Ultimately, the advantages of corrective maintenance lie in its flexibility, cost efficiency, and potential for continuous improvement. While it may not be suitable for every situation, it remains an important tool in the broader maintenance toolbox. When applied thoughtfully, it can help businesses maintain performance without unnecessary expense or complexity.